Industrial Management printed circuit board (PCB) assembly is with the Main of modern producing and automation units. As industries strive for higher effectiveness, precision, and reliability, developments in PCB assembly Engage in a pivotal function in Conference these calls for. This doc explores the emerging tendencies and groundbreaking innovations shaping the way forward for industrial Manage PCB assembly, providing insights into how technological know-how is revolutionizing this vital discipline.

Table of contents:

The Evolution of Industrial Regulate PCB Assembly

State-of-the-art elements in PCB Assembly for Industrial Applications

issues and methods in large-general performance Industrial PCB Assembly

The Evolution of Industrial Management PCB Assembly

Industrial Handle PCB assembly has undergone major transformations lately, driven by progress in know-how as well as the increasing desire for high-overall performance and reputable electronic solutions. The evolution of producing processes, like surface area mount engineering (SMT) and through-gap click here know-how (THT) assembly, has been pivotal in obtaining larger effectiveness and precision. businesses like Mango Option, noted for their comprehensive PCB assembly providers, have leveraged chopping-edge capabilities, including multi-layer PCB assembly and Innovative tests techniques, to satisfy developing industrial demands. With their power to develop around 5 million placements per day and produce PCBs in as tiny as two days, brands have embraced streamlined workflows and ground breaking strategies. Automation and robotics in PCB assembly spotlight developments in the sector. Automated high quality checks, AOI inspections, and X-Ray technologies lessen problems, guaranteeing precision and regularity. Custom alternatives like box builds and wire harness assemblies have expanded prospects for industrial Management PCBs. Balancing Price tag performance with high efficiency, fashionable PCB assembly is driving a foreseeable future where innovation meets practicality.

Superior resources in PCB Assembly for Industrial Applications

The choice of supplies Employed in PCB assembly is a critical factor in determining the efficiency, longevity, and reliability of industrial control methods. Advanced products including large-Tg laminates, ceramics, and polyimides are actually far more commonplace for managing the thermal and mechanical stress connected with demanding environments. Copper, with its superb conductivity, continues to be an ordinary preference, but modern innovations have introduced alloys and composites to aid unique use-case necessities. Mango Option’s PCB assembly providers provide finishes like HASL, immersion tin, and electroless gold plating, personalized for different industrial applications. These coatings boost electrical efficiency and shield circuit boards from oxidation and degradation. resources like solder mask, silkscreen, and laser-Lower chrome steel stencils even further enhance toughness. The increase of eco-welcoming resources can be shaping the market, with companies adopting direct-absolutely free soldering and sustainable packaging. higher-effectiveness resources and eco-helpful processes are redefining the potential of industrial Command PCB assemblies.

Challenges and remedies in substantial-overall performance Industrial PCB Assembly

Irrespective of sizeable developments, troubles remain in industrial control PCB assembly. vital concerns include things like acquiring dependable efficiency throughout production cycles though trying to keep charges aggressive. Component miniaturization, escalating circuit complexity, and thermal administration insert additional pressure to assembly procedures. To deal with these, organizations like Mango Solution use substantial-high-quality parts, strict excellent Management, and specialized screening like ICT and program burn off-in exams. Additionally they source alternatives or pin-to-pin equivalents for rare or highly-priced factors, making sure Price-performance and avoiding creation delays. Customization is yet another challenge, as industrial purposes generally demand customized PCBs. Mango Remedy meets this want with versatile board assembly and prototype output as compact as five parts, creating tailor-made alternatives available to equally startups and set up enterprises. Scaling manufacturing without sacrificing high quality is an additional worry. Mango Resolution’s strong production capacity, coupled with automated assembly procedures, makes sure effectiveness and precision, delivering reliable solutions for swiftly rising industries.

the worldwide shift toward Superior industrial Management methods depends seriously on innovation inside PCB assembly. Combining economical procedures, reducing-edge components, and adaptive answers makes certain marketplace leaders like Mango Remedy are Geared up to satisfy the requires of the quickly-evolving sector. for people in search of trusted and economical PCB assembly solutions, companies within the forefront of innovation, like Mango Answer, present remarkably Superior PCB abilities that allow corporations to stay aggressive and generate achievements in their functions.

Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Ross Bagley Then & Now!

Ross Bagley Then & Now! Danny Pintauro Then & Now!

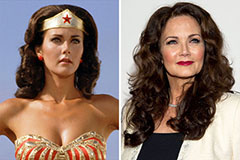

Danny Pintauro Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!